Bluetooth low energy, also known as Bluetooth LE or BLE, is a relatively new communication technology designed for use with devices connected to the internet. There are several industries that are already incorporating BLE, such as healthcare, fitness and security, but the potential benefits of using it in other industrial sectors are now also being realised. For example, BLE can help to streamline onsite processes around automated construction inventories, theft prevention and managing the performance of equipment.

What is BLE?

BLE is a secure and simple wireless network technology with a lower power consumption and lower cost compared to Classic Bluetooth yet with a similar range of communication. It is supported on a variety of operating systems, including iOS, Android, macOS, Linux and Windows 8 onwards. Compared to other related technologies, such as barcode scanning, GPS, Wifi and RFID, BLE has certain advantages in terms of flexibility, reliability and opportunities for integration.

In the home environment, Classic Bluetooth is often used to connect everyday devices, such as wireless speakers, mobile phones or cameras. However, with its low power consumption, low cost and ease of attaching to assets, there are also opportunities for BLE sensors to be used in the construction industry and fitted to equipment onsite.

By using conventional approaches in construction it can be very difficult to keep track of where equipment is located onsite, how much it is being used and how worn out it is. As a consequence, the management of these assets can be time consuming, reactive rather than proactive and prone to errors, which will all negatively affect the company’s bottom line.

How can BLE be used in construction?

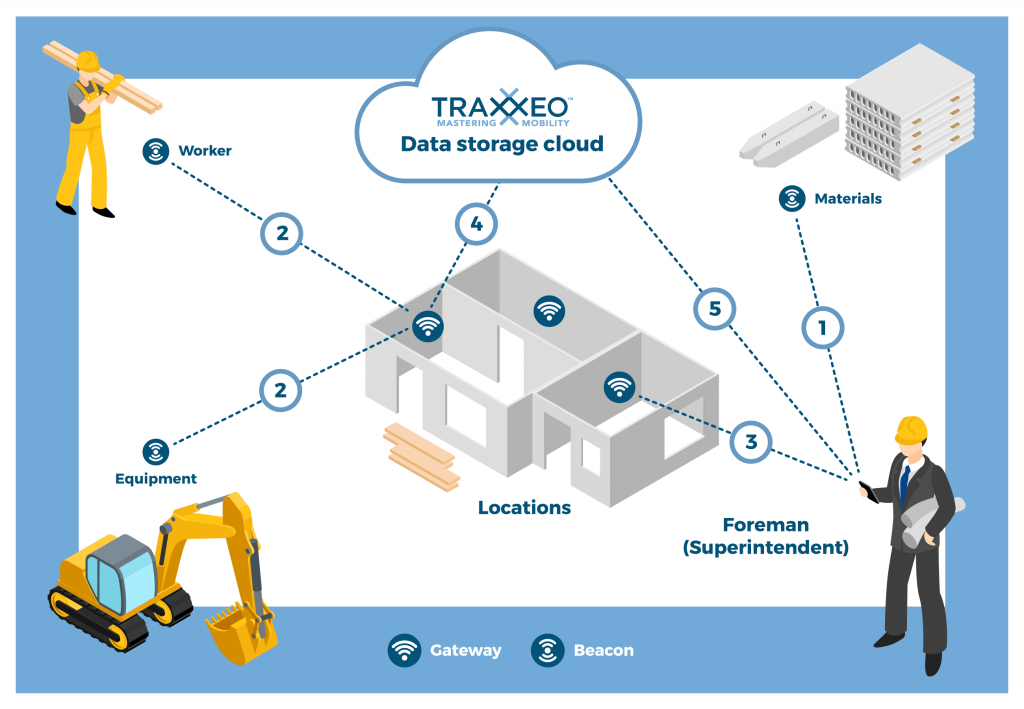

Due to the relatively small size of BLE technology and its associated low power requirements, it can be easily fitted on to tools and equipment, or even attached to personnel. The BLE signal is then transmitted by a beacon and picked up by a detector, before being sent to a controlling operating system that provides accurate real-time information to users, as shown below. Also, the technology is long-lasting and can be moved from site to site, or machine to machine, which ensures its usefulness over many years.

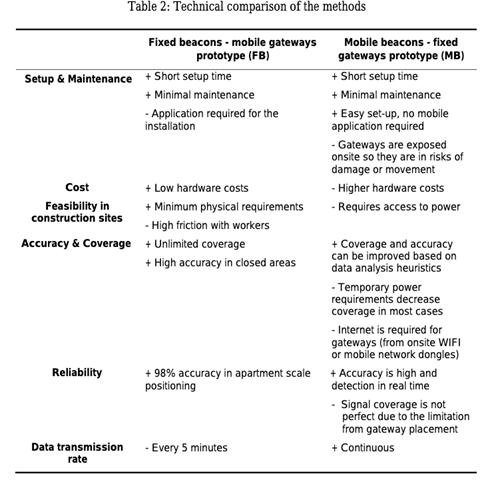

In terms of data gateways, there are options around implementing (1) mobile beacons and fixed gateways (MB), or (2) fixed beacons and mobile gateways (FB) – a recent conference paper on using these technologies for the indoor tracking of construction workers helpfully summarises and compares these arrangements. Generally, there are three different types of data gateways that can be used with BLE, such as:

- Mobile device (tablet or smartphone) – Bluetooth is already a commonly used feature with these devices and they work alongside fixed beacons, meaning that they are ideal for monitoring workers;

- Onsite terminal – a fixed gateway is often appropriate for providing data about static or fixed assets onsite;

- Vehicles and plant with specific gateways installed – these allow the tracking of mobile assets and will transmit data regardless of who, if anyone, is operating the equipment, which can add another layer to security procedures onsite.

Benefits of BLE in construction

The application of BLE on construction sites clearly has considerable scope to help with the management of equipment and personnel by site managers and human resources. For example, using BLE onsite can allow the company to:

- improve the tracking of assets and easily identify the location of a piece of equipment;

- maintain an accurate automated inventory of assets that is updated in real-time;

- monitor the utilisation rate of equipment and promptly take any actions, such as servicing or replacement, that are needed.

The benefits of incorporating this BLE technology are that valuable hours are saved in gathering vital site information, opportunities for the onsite theft or loss of equipment are reduced and equipment can be proactively managed in a timely manner which will reduce costly downtime. There are also advantages in terms of the health and safety of workers because the location of personnel in any potentially hazardous area can be quickly identified. Plus, it is possible to remotely monitor the temperature of a worker and it can also be seen when there is a ‘man down’.

A comparison of the pros and cons of FB versus MB is shown below. Overall, FB are cheaper and have unlimited coverage with high accuracy in closed areas, but its success relies on the actions and cooperation of workers and data transmission is not continuous. Alternatively, MB are easier to set up and have continuos data transmission, although there are greater hardware costs, coverage can be patchy and access to power is required.

Dror, Zhao, Sacks and Seppänen

At Traxxeo, we have developed digital tools to simplify resource management and allow construction companies to have a clear overview of their onsite assets. This is managed by:

- using a smartphone to geolocate the equipment onsite as soon as it is detected by the BLE technology. Mobile applications are available for site managers, security personnel, team leaders and other key people to follow up and take any necessary actions;

- centralising all the data collected from the different smartphones on our web platform, allowing automated site inventories to be maintained that are accurate and up to date.

Return on investment in BLE

Information is priceless in any industry and the construction sector is certainly no different. Data from connected objects for construction provides real-time information that was previously unavailable and this will improve production processes, site management and, more broadly, management control.

Thanks to increasing demand for the technology, BLE is becoming ever more accessible for all sizes of construction companies. The significant costs attached to much construction equipment, not to mention related labour costs, mean that better management and control of it will ultimately provide a valuable return on investment in BLE.